A Turnkey Microfluidic System

Unlock New Insights in Industrial Fluid Analysis

Introducing ground-breaking capabilities for microfluidic testing at unprecedented pressures, temperatures and automation.

Who Uses SapphireLab

Safe, High Pressure and High Temperature Microfluidics

SapphireLab enables your team to safely conduct high pressure (up to 1,034 bar or 15,000 psi) and high temperature (up to 200°C or 390°F) microfluidics tests. Microfluidics is inherently safer than traditional methods that require 10 to 100 times more sample volume per test, and SapphireLab takes it further by integrating mechanical and software features, such as burst disks for pressure relief, that reduce risks to your team. We use SapphireLab in our own laboratory, and understand the need for a safe work environment.

Accelerate Research

With SapphireLab, your team can concentrate on science rather than the technology. Its intuitive hardware and software platform streamlines your workflow, allowing you to spend more time generating results instead of sourcing components or troubleshooting image issues. Most tests can be completed in under a day, enabling you to achieve faster results than traditional testing platforms or DIY microfluidics setups.

Small But Mighty

With a footprint about the same size as a typical dishwasher, SapphireLab can fit in even the most space-constrained laboratories. Out-of-the-box, SapphireLab is a multipurpose instrument capable of supporting many fluid property tests and interaction behavior tests, giving it one of the best capability to footprint ratios of any fluid analysis instrument. Combined with your expertise and know-how, SapphireLab is flexible enough to support your changing research needs, and small enough to fit within the laboratory space you already have.

Optimize Chemical Screening for Customer Projects

Because we can accurately manufacture many microfluidic chips with the same specifications, and SapphireLab tests can typically be done in a day, you can rapidly screen chemistries to pick the best performer for a given reservoir or facility operation.

Accelerate New Product Development

Microfluidic tests are fast and inherently repeatable due to the ability to manufacture many microfluidic chips with the same specifications. The technology is great for tuning chemical formulas—whether for surfactants used in hydraulic fracturing, or wax inhibitors used in managing flow assurance issues.

Gain Competitive Advantage

Gain a competitive advantage by clearly demonstrating to your customers the effectiveness of your chemistries at reservoir pressure and temperature.

Launch a New Revenue Stream

While SapphireLab can be a value-add service provided to customers of your products, it can also support fee-for-service chemical screening. SapphireLab customers use measured results and images taken during tests to demonstrate the effectiveness of their chemical products against a control and competing products.

Increase Production

SapphireLab’s unique rapid chemical screening capabilities enables Completion Engineering teams in unconventional production to optimize hydraulic fracturing fluid packages for increased production. Through fine tuned control of oils, surfactants, water sources, porous media structure, and operating pressure and temperature, teams can trial different chemistries and concentrations at low cost and zero risk, to identify the best performing fluid packages. If desired, teams can then test the best performing fluid package in a core flood to validate results and measure the impact of rock-fluid interactions, before moving to the well.

Prevent Overspending on Chemistry

When it comes to surfactants and flowback aids, using more than the optimal dosage can diminish the ability of oil to flow from the producing formation. In addition to selecting the correct concentration of a flowback aid, SapphireLab can also provide insight into the fluids package to ensure that there are no chemical-chemical or chemical-water incompatibilities by testing whole fluid systems, in addition to testing components in isolation.

Reduce Down Time

Production Engineers know even small changes in incoming fluid composition can result in costly production down time. That’s why great care and effort is focused on regular monitoring of wax, emulsions, and scale in production volumes. Because microfluidic tests are highly sensitive, Production Engineering teams can integrate SapphireLab into their monitoring program to accurately detect small fluid changes and serve as an early warning system for flow assurance issues.

Reduce Chemical Costs

Through fast and repeatable chemical screening with SapphireLab, Production Engineering teams can better optimize chemical dosing levels, potentially reducing the cost of flow assurance programs for wax, scale, asphaltene and emulsion problems. SapphireLab provides more data, like particle size distribution,to better differentiate products on the market and understand the “why” behind chemical performance.

Increase Production

SapphireLab’s unique rapid chemical screening capabilities enables Reservoir Engineering teams to identify and optimize enhanced oil recovery processes such as chemical injection, gas injection, and thermal processes. Through fine tuned control of oils, gases, water, porous media structure, and operating pressure and temperature, teams can trial different chemistries and concentrations at low cost and zero risk, to find the best performer. If desired, teams can then test the best performing fluid package in a core flood to validate results and measure the impact of rock-fluid interactions, before moving to the well.

Reduce Formation Damage Risk

Just as SapphireLab can be used to rapidly screen chemistries for optimizing oil production, it can also be used to reduce the potential for formation damage resulting from incompatible fluids in a reservoir. Common examples include incompatible surfactants, waters and oils in hydraulic fracturing and enhanced oil recovery, and identification of flow assurance issues due to wax, asphaltenes, scale and emulsions. With SapphireLab you can both measure and observe the interaction of fluids at pore scale, making it easier to quickly understand what is happening and to identify a solution.

Accelerate Project Delivery

With most SapphireLab fluid tests being completed in about a day, there is significant potential to accelerate timelines for routine tests like core floods and slim-tube tests, or longer-term research and development fluid projects. While SapphireLab can be used as a pre-core flood chemical screening tool, making better use of valuable core and fluid samples.

Add New Capabilities

SapphireLab is a multi-purpose tool, supporting a range of fluid applications from chemical screening to phase behaviour studies. SapphireLab helps Service teams manage a variety of requests by supplementing existing capabilities or adding completely new revenue opportunities, without the need for dedicated equipment. SapphireLab can be easily configured to new capabilities in the future as client priorities change, without needing to purchase new equipment.

A Multi-Purpose Tool for Fluid Analysis

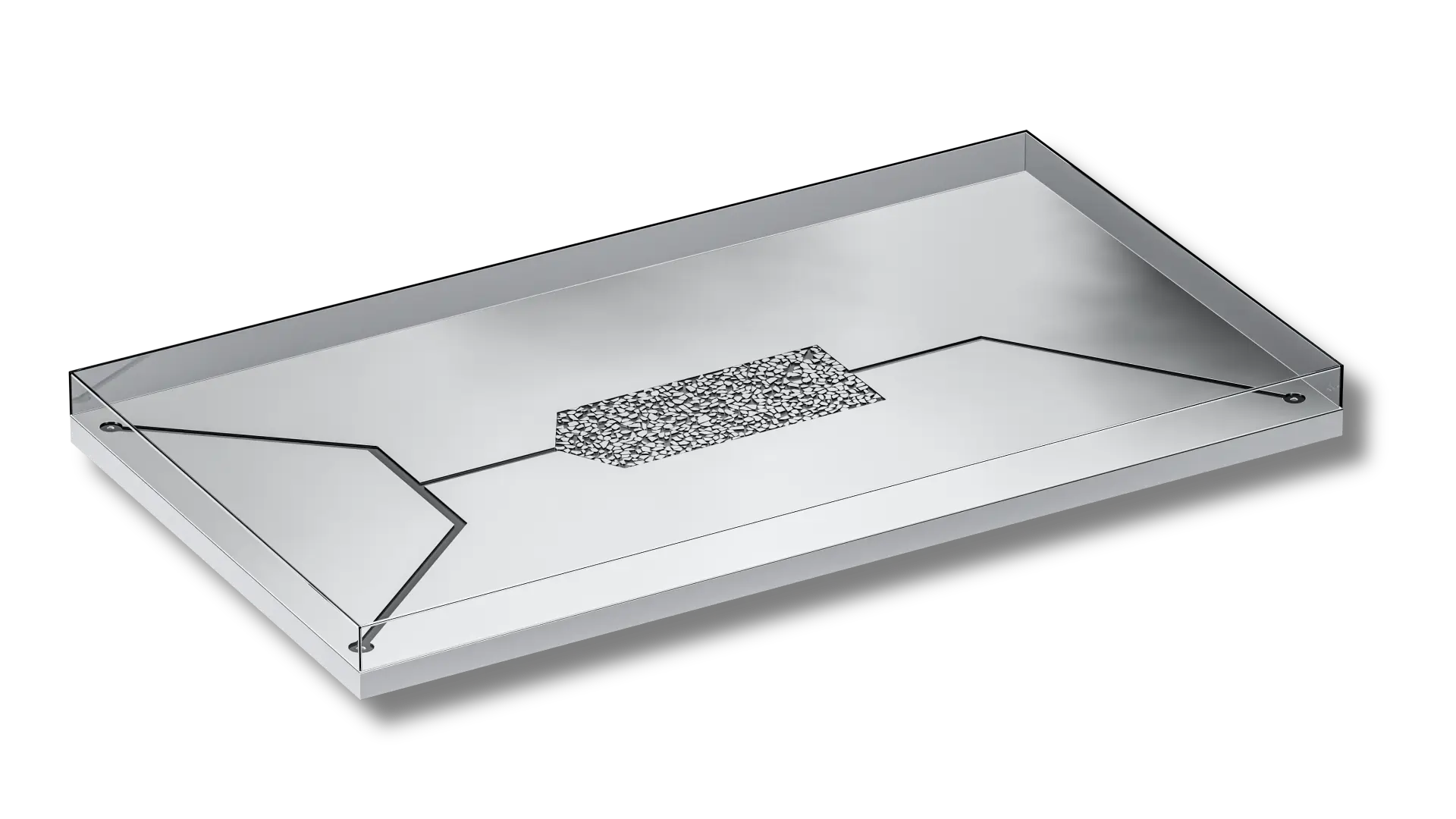

SapphireLab is a ready-to-use solution that can handle most of the work done today by a PVT Cell, Core Flood, Slim Tube, Proppant Pack and other specialty tools.

Deeper insights into fluid behaviour with a single system:

- Carbon storage

- Flow assurance

- Formation damage

- Enhanced oil recovery

- Completion fluid evaluation

- Phase Behaviour

- And more

Next Generation Fluid Analysis For Your Laboratory

SapphireLab leverages microfluidic technology to deliver critical data about how fluids behave underground. Our customers can increase production and reduce expenses by:

- Visual access

- Reduced sample requirements

- Highly controlled and customizable porous media