Minimum Miscibility Pressure (MMP) and Composition

PVT & FLUID PHASE BEHAVIOUR

Rapid measurements for gas flooding

Quickly determine miscibility conditions for your gas flooding operation with a variety of gas compositions. MMP measurements provide you the minimum pressure required for miscible oil displacement in your reservoir. This critical measurement helps you avoid unwanted early gas breakthrough, which reduces oil recovery.

Developed in partnership with Equinor, this test is proven to deliver accurate results in as little as 30 minutes with as little as 0.1ml of oil sample per data point.

Publications

Large-Scale High-Throughput Sensitivity Analysis of CO2 MMP to Optimize Gas Injection EOR Processes

A. Abedini, Z. Qi, T. de Haas, and D. O’Brian, Interface Fluidics Ltd., Calgary, Alberta, Canada

SPE-216683-MS

A B S T R A C T

Performance of CO2 injection relies on accurate CO2 MMP/miscibility data at reservoir conditions. The CO2 stream typically contains gas impurities, and in most cases CO2 is combined with recycled gasses, which in either case the MMP changes – imposing additional uncertainties to deviate from expected CO2-MMP. Slim-tube is the most reliable tool; however, it is very time- and capital-intensive, making it impossible to provide high-throughput data to assess the impact of other gasses.

A new fluidics method to determine minimum miscibility pressure

Frode Ungar, Sourabh Ahitan, Shawn Worthing, Ali Abedini, Knut Uleberg, Tao Yang

Journal of Petroleum Science and Engineering

Volume 208, Part B, January 2022, 209415

A B S T R A C T

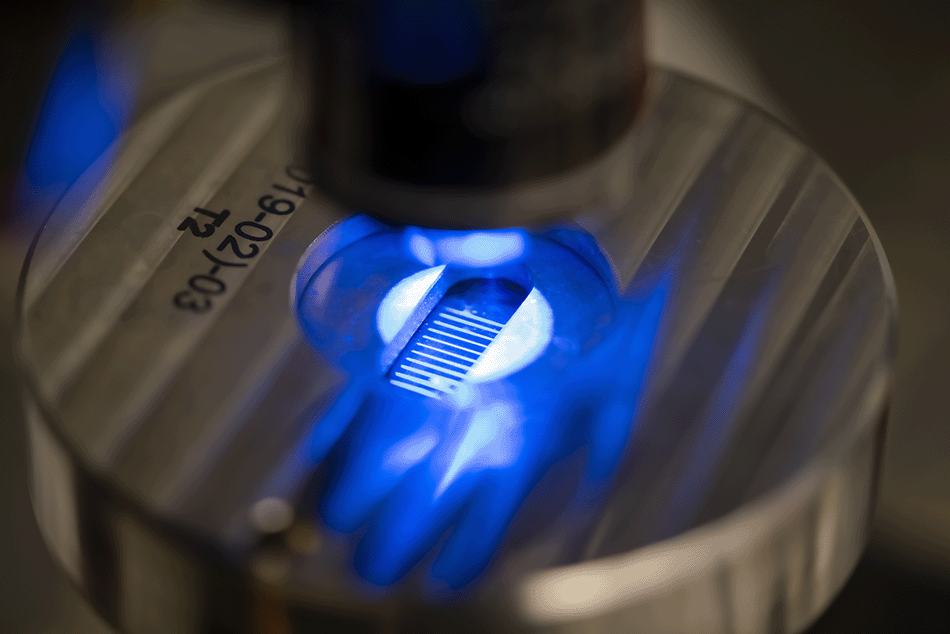

Micro and nano-fluidic devices have attracted increasing attention in the oil industry. In this study, we designed a new slim-tube method to determine MMP on a microfluidic chip. The design is significantly different from previous efforts on fluidics chips with an open flowing tube. The new design contains porous media similar to that found in the slim-tube apparatus. The objective is to produce a true multi-contact process in the gas displacement. We tested the new fluidics device at reservoir conditions with three reservoir oils displaced by two hydrocarbon gases and CO2 gas.

Case Study

Minimum Miscibility Pressure (MMP)

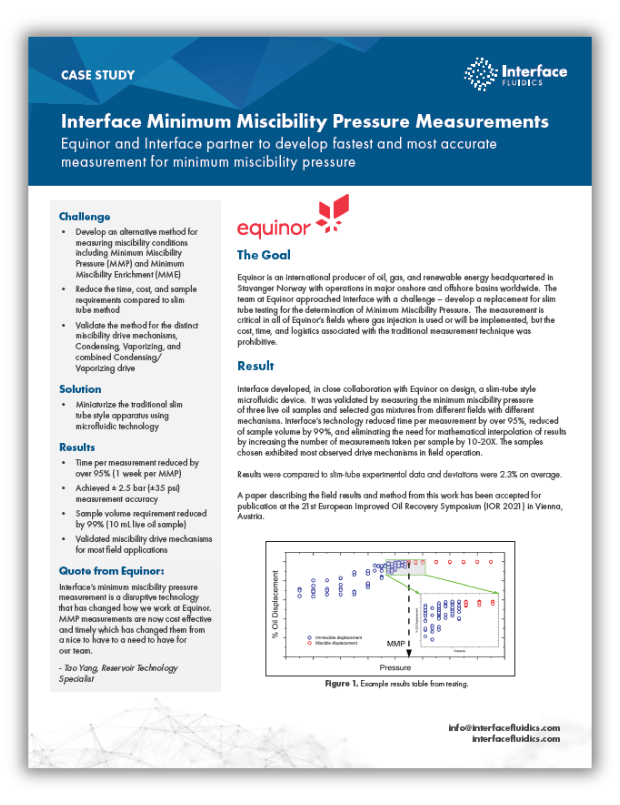

The team at Equinor approached Interface with a challenge – develop a replacement for slim tube testing for the determination of Minimum Miscibility Pressure. The measurement is critical in all of Equinor’s fields where gas injection is used or will be implemented. But the cost, time, and logistics associated with the traditional measurement technique was prohibitive.

In close collaboration with Equinor on design, Interface developed a slim-tube style microfluidic device. It was validated by measuring the minimum miscibility pressure of three live oil samples and selected gas mixtures from different fields with different mechanisms.

Brochures

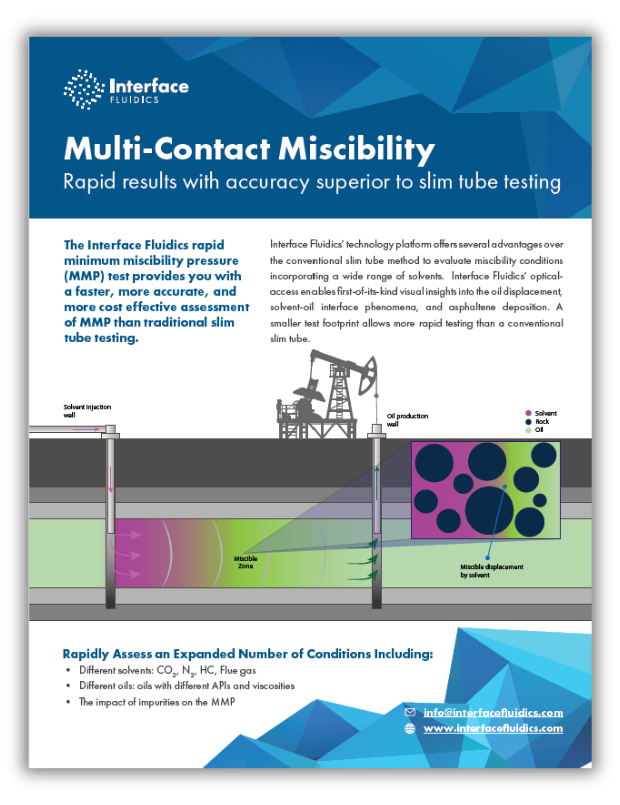

Multi-Contact Miscibility

Interface Fluidics’ technology platform offers several advantages over the conventional slim tube method to evaluate miscibility conditions incorporating a wide range of solvents. Interface Fluidics’ optical access enables first-of-its-kind visual insights into the oil displacement, solvent-oil interface phenomena, and asphaltene deposition. A smaller test footprint allows more rapid testing than a conventional slim tube.

Interface’s technology:

- reduces measurement time by 95%;

- reduces sample volume by 99%;

- eliminates the need for interpolation of results by increasing the number of measurements taken per sample by 10-20X.