Surface Solutions

What is Happening In Your Assets

Solutions focused for Flow Assurance and Product Chemistry

Characterizing Fluids

The Problem

Maintaining asset integrity while figuring out the best fluid pumping options at different stages of oil field development is a big challenge.

The Root Cause

Inconsistent and unreliable third-party testing can create a lot of uncertainty about how fluids interact. This uncertainty can lead to inaccuracies, causing operational inefficiencies, safety risks, and higher costs.

The Solution

Predicting and Mitigating

The Problem

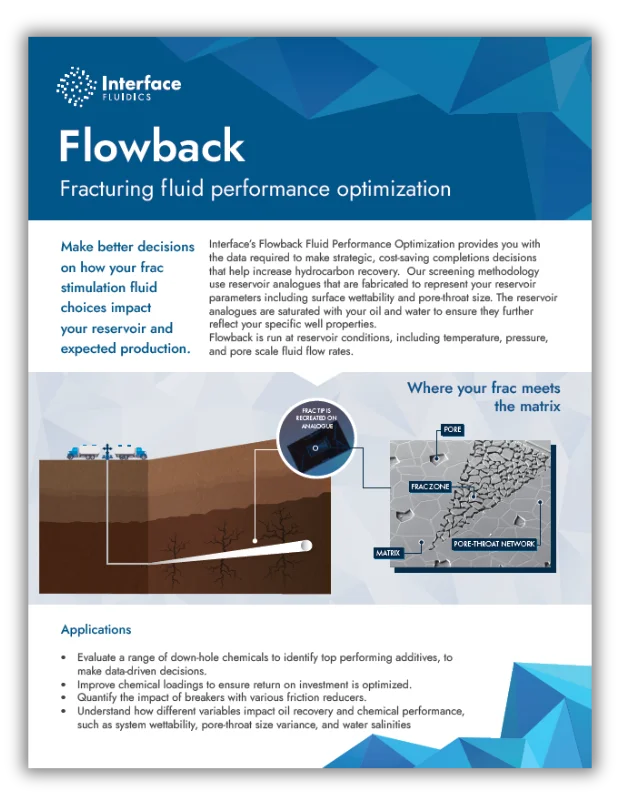

Testing fluid behavior under reservoir conditions, like high temperature and pressure, can be challenging. These extreme conditions can change the physical and chemical properties of fluids, making it tough to accurately predict how they’ll interact.

The Root Cause

Traditional lab tests are often too slow and rigid to provide useful data, quickly. They don’t adjust well to changes in variables, which can delay critical decision-making.

The Solution

Preventative Solutions

The Problem

Testing “what if” interactions of different chemistries for each unique site can be expensive, non repeatable, and time consuming.

The Root Cause

Testing is often done in-line rather than under conditions that mimic real-world facility changes. As a result, the outcomes might not accurately reflect how systems will perform in actual operations.

The Solution

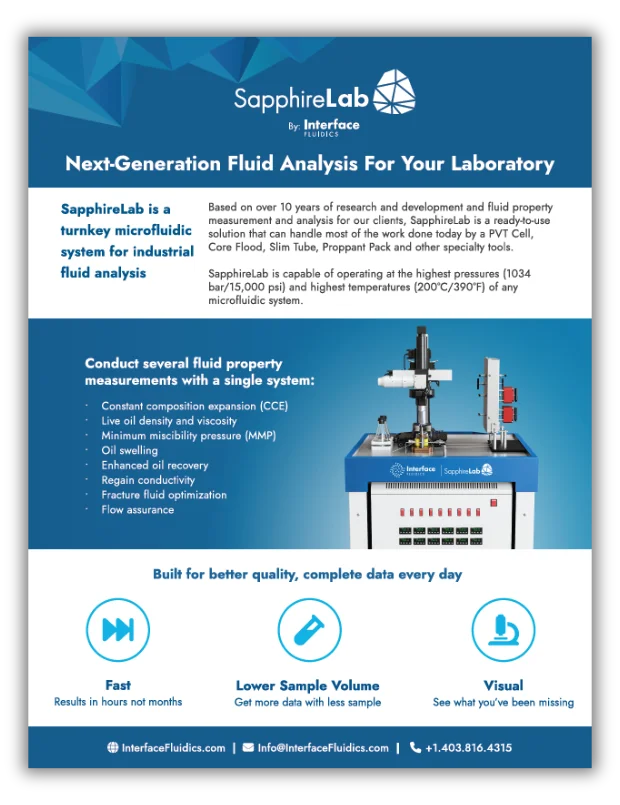

SapphireLab performs real-time testing, providing immediate insights that mirror the rapidly changing conditions of your facility. This dynamic approach allows for effective exploration of all those “what if” scenarios, whether onsite or in a lab.

Problem Solving

The Problem

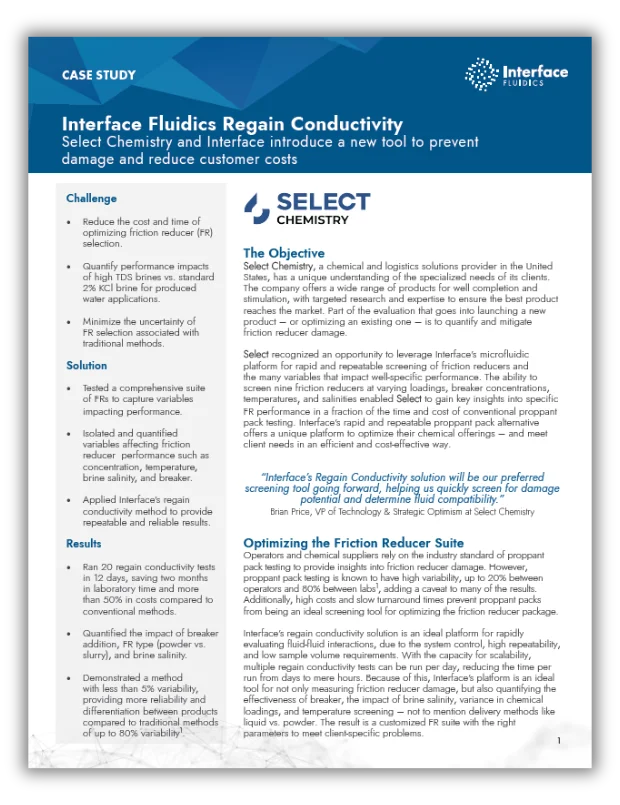

Optimizing friction reducer selection and understanding its performance can be both expensive and time-consuming. Traditional methods often introduce a lot of uncertainty, especially when you’re dealing with different brine conditions.

The Root Cause

Traditional testing methods are often slow and inflexible, and they don’t adapt well to changes in variables like concentration, temperature, brine salinity, and breaker addition. This leads to unreliable data, making it difficult to make informed decisions.

The Solution

SapphireLab offers a more efficient and reliable way to test friction reducers. By isolating key variables and using our advanced regain conductivity method, we provide fast, repeatable results. This approach cuts down on testing time and costs while delivering precise data, helping you make better decisions, quickly.