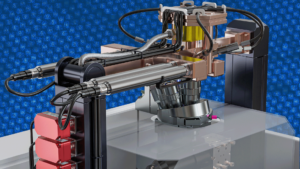

Two months after closing a Series B fundraise, Interface Fluidics has announced a joint industry project (JIP) with Equinor and ExxonMobil to accelerate the deployment of the world’s first compact, rapid fluid screening equipment for oil and gas. Essentially a portable laboratory, this technology will revolutionize pressure-volume-temperature (PVT) testing, an essential part of the exploration and production process for the oil and gas industry.

After the successful demonstration and pilot of Interface’s miniature slim tube system developed in partnership with Equinor, the companies are coming together to expand the capability of the technology to include the remainder of the standard oil and gas characterization tools such as constant composition expansion, gas/oil ratio, LVR, live oil viscosity and density, and swelling in the suite of PVT capabilities.

This new platform will build on Interface’s existing work, which has demonstrated significant advantages compared to traditional oil and gas testing options. For instance, when compared to other options for testing minimum miscibility pressures (MMP), Interface Fluidics provides measurements that:

- Are at least 50% less expensive

- Require 99% smaller samples

- Deliver results 95% faster

- Remove the need for interpolation

“This project, while intended to make field decisions easier, goes far beyond traditional oil and gas testing options, to include carbon capture utilization and storage insights, as well as the ability to optimize the design of surface facilities and full-field development,” says Stuart Kinnear, CEO & Co-Founder of Interface Fluidics.

“It is exciting to start the JIP aiming for a complete new PVT solution with large potential to change the current way of working. Based on our experience with the talented development team at Interface, we have high confidence for fruitful results from close collaborations between Interface and all partners,” says Tao Yang, PVT specialist at Equinor.

The partnerships made with this JIP will mobilize Interface’s technology platform into the hands of consumers. By making critical fluid property data accessible, it may open up new methods for developing and managing oil and gas production that could avoid significant GHG emissions. Re-injecting gas that might have been flared for Enhanced Recovery is one such application. It will also make the collecting and testing of samples more convenient for field use, potentially saving the industry hundreds of millions of dollars.

This technology generates data that can facilitate the reduction of chemical and freshwater usage, and emissions uniquely accessible, by providing an exponentially faster, on-demand approach. The method will enable quicker, more affordable sampling, shipping, and testing, allowing for expedited results and solutions.