Blog

Stay Up To Date

Stay up to date on all the news and technology coming from Interface Fluidics.

Latest News

Formation Water Reinjection: How Damage Impacts Reservoirs

Almost 20 years after the advent of fracking, produced water management remains a challenge costing oil and gas tens of billions of dollars per year. And with mounting environmental regulations, the universal solvent has long made its way to the boardrooms of petroleum companies – to figure out ways to get the most out of this untapped resource. At Interface Fluidics, we believe in a centralized approach to formation water

A New Tool for Flow Assurance and Measuring Wax Deposition

Flow assurance in general, and wax deposition in particular, is a problem as old as the petroleum industry itself. It is estimated to cost around $330 billion per year when the impact of oil spills is considered. While there are a variety of ways to prevent and resolve this issue, there is still no one-size-fits-all solution. In recent years, chemical treatment has garnered a lot of attention as it offers

Advanced Technology in Hydrocarbon Extraction

The oil and gas sector’s digitization presents an opportunity to the tune of $2.5 trillion of value – and over a billion tonnes of emissions and 800 million gallons of water-use reduction by 2025. However, the World Economic Forum reports the industry has been slow to adapt to the ongoing digitally-fueled transition. Software innovations driving this transformation include the Internet of Things (IoT), big data and analytics, system integration, computer

Cutting-Edge Microfluidics for the Hydrogen Age

There is growing confidence that hydrogen is set to be the next big thing for the world’s energy landscape. Its market is expected to be worth $2.5 trillion by 2050. This has spurred much technological innovation, and Interface Fluidics is joining the hydrogen age research early. Interface’s microfluidic technology aims to measure the physical properties of H2 and its mixtures. In doing so, we’ll combine multiple critical measurements, and reduce

Lab on a Chip Adds Fluid Testing to Oil and Gas Workflows

Oil and gas companies understandably devote a lot of attention to optimizing workflows to maximize value in their operations. Robust and ongoing fluid testing should be a part of this process. However, conventional tests can be so inconvenient that operators are often left with limited options. This is where lab on a chip technology comes in. Proper reservoir fluid screening contributes to all the components of a successful, efficient production

The Journey of an Oil and Gas Startup

Every year more than a thousand start-ups are born, many with the potential to disrupt the oil and gas industry. And while over 63% of entrepreneurs start a business with a view towards change, 20% of new businesses fail in the first year and 50% in the first five years. Interface Fluidics was once just an idea hoping to make a difference. But with the right technology, we’ve made it

Produced Water Reinjection for Reservoir Production

Water use is an inseparable part of oil and gas production. H2O can be injected into hydrocarbon reservoirs as a secondary flood, be combined with chemicals like surfactants and polymers in Enhanced oil recovery (EOR) and plays a crucial role in hydraulic fracturing and the generation of steam for SAGD processes. Different applications Waterflooding is the process of injecting water to increase production from oil reservoirs. It typically follows primary

Lab On a Chip Vs. Traditional Hydrocarbon Fluid Analysis

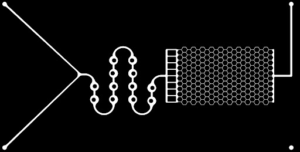

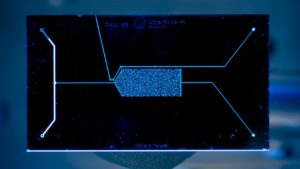

Interface Fluidics offers fluid testing services for energy companies to gauge fluid compatibilities, boost reservoir yield, mitigate chemical damage, and cut down on risk and cost. What’s different about Interface is that our equipment uses a microchip smaller than the face of a watch. Our technology can replace slim tube, proppant pack, core flooding, column drainage, beaker scale tests, and more. All of these test options will soon be capable

Surfactant EOR Optimization Through Wettability Alteration

Interface Fluidics provides testing services for energy operators that cover a slew of measurements. One of our valuable analyses involves the screening of chemical additives for enhanced oil recovery (EOR). These chemicals can include surfactants, polymers, CO2 foams, solvents, nanofluids and more. While all of these are important, surfactants are a big part of the work we do at Interface – so here’s a more in depth look at them.

The Peclet Number and How It Describes Fluid Transport

Underground fluid interactions take place between miscible fluids (oil and miscible CO2) and immiscible fluids (water and oil). Many factors determine the transport of fluids, one of which is fluid mixing. In most conditions, mixing in a reservoir is due to a combination of advective transport and diffusive transport. The ratio of the rate of these two transport mechanisms, known as the Peclet number, can be used to characterize flow

Designing A Compact Lab for Reservoir Fluid Testing

Recently, Interface Fluidics announced the release of SapphireLab, a revolutionary product in its class. SapphireLab brings together the three core technologies that we have been developing over the past six years into one product: microfluidic chip design, mechanical design, and software. The design of high-pressure, high-temperature fluid systems has been my passion since I flooded a portion of my elementary school gym demonstrating the Hagen–Poiseuille equation. I’ve learned a bit

The Importance of Capillary Pressure for Oil and Gas

Interface Fluidics is a leader in creating microfluidic reservoir-mimicking chips, which we use to conduct a variety of measurements. When designing microfluidic systems, many factors must be taken into account. One of these is capillary pressure. So, what is capillary pressure? It’s defined as the pressure that is generated when two immiscible fluids are in a narrow channel or tube. This pressure becomes important when describing fluid flow in an