Blog

Stay Up To Date

Stay up to date on all the news and technology coming from Interface Fluidics.

Latest News

Onsite Oilfield Testing, a Not So Distant Future

From the beginning, the goal of Interface Fluidics has been to make high pressure, high temperature (HPHT) measurements accessible to the oil and gas industry using microfluidics. Applying this technology to energy left a lot of room for potential growth. After all, it’s been used by the biomedical sector for years. Microfluidics for oil and gas isn’t new – companies have known about the advantages for more than 70 years.

Portable HPHT Testing Breaks Ground

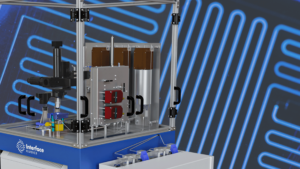

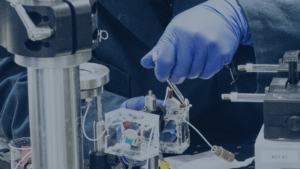

As the oil and gas industry rethinks its approach to minimum miscibility pressure (MMP) measurements, Interface Fluidics is pleased to announce the development and deployment of a first-of-its-kind portable testing system. Showcasing Interface’s unique, nanotechnology-enabled, microfluidic MMP screening, this device will support the optimization and de-risking of carbon capture, utilization, and storage (CCUS) processes. By calibrating the blending of multiple produced gas streams and industrial CO2, Interface will provide operators

Carbon Capture and Storage – the Path Ahead

With climate change dominating headlines, you’ve probably heard a thing or two about carbon capture and storage (CCS) – unless you’ve been living under a rock. If you haven’t, that’s not necessarily a bad thing. “Living” under a rock is exactly what operators hope to accomplish with injected CO2. Carbon dioxide storage employs diverse mechanisms with varying degrees of maturity. It can take place in depleted oil and gas reservoirs

Permian Basin EOR: Profiles in Innovation

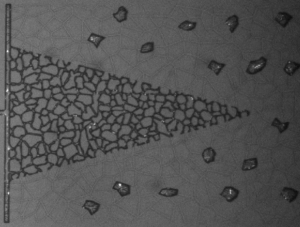

Commercial microfluidic screening from Interface Fluidics is prime for use in the enhanced oil recovery (EOR) of unconventional reservoirs. Comprehensive case studies published in OnePetro detail the technology’s capabilities and advantages. EOR can generally be divided into chemical, thermal, and gas injection methods. For unconventional reservoirs like the Permian Basin, CO2 injection and surfactant-based chemical EOR have been reported as the most effective. However, traditional core flooding is limited when

The Origins and The Future of Microfluidics in Energy

By definition, microfluidics is the science and technology of analyzing or processing fluids in channels from 1 to 1000 microns in diameter. Put in perspective, a single strand of hair is around 100 microns wide. The use of this technology in the oil and gas industry has a complex history that brings together aspects of molecular analysis, biodefense, molecular biology, microelectronics, and reservoir engineering. While it has its roots in

Smaller Is Better? HSE Benefits of Working with Interface

The Health, Safety, and Environmental (HSE) aspects of reservoir fluid analysis are a priority for Interface Fluidics. While traditional lab analysis requires multi-liter samples, Interface’s microfluidic technology cuts that down to a few milliliters – which diminishes HSE impacts like the potential release of hazardous substances. Advantages of smaller sample sizes include easier and more energy-efficient collection, as well as convenient and cost-effective shipping. For Interface, the reduced sample size

Interface Thief Zone Research Published in Fuel

Research by Interface Fluidics into enhanced oil recovery (EOR) provides a way to comprehensively analyze thief zones and now this work has been published in the journal ‘Fuel’. Interface’s microfluidic technology not only provides more and better data about EOR but can also provide cost savings and lead to cleaner operations. Polymer flooding has been in use for decades and involves the injection of polymer-augmented water into oil fields to

Testing Fracturing Fluids for Optimal Reservoir Permeability

Hydraulic fracturing – or fracking – is a technique used to access tight reservoirs by blasting water, sand, and chemicals into the formation, breaking them open, and allowing oil and gas to flow back to surface. The hydraulic fracturing fluids used are a sort of cocktail of chemicals from friction reducers and biocides to surfactants and nanofluids. The chemicals added to a fracturing fluid each serve different purposes, whether that’s

Interface Fluidics announces joint industry project with Equinor and ExxonMobil

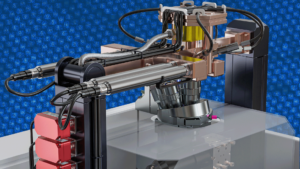

Two months after closing a Series B fundraise, Interface Fluidics has announced a joint industry project (JIP) with Equinor and ExxonMobil to accelerate the deployment of the world’s first compact, rapid fluid screening equipment for oil and gas. Essentially a portable laboratory, this technology will revolutionize pressure-volume-temperature (PVT) testing, an essential part of the exploration and production process for the oil and gas industry. After the successful demonstration and pilot

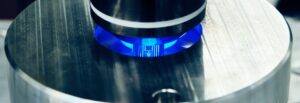

Video: Raising the Bar on Pressure Capabilities

At Interface Fluidics, we’ve seen the impact that microfluidics testing has had in the biomedical sector and we’re bringing the power of microfluidic technology to the energy industry. Just as a device used on blood needs to match the conditions of the human body, a device used to measure fluids underground needs to be at the appropriate pressure. Interface has been continuously developing fluid analysis systems that deliver category leading high-pressure

Interface Fluidics Raises $6.7 Million in Investments

Interface Fluidics has secured $6.7 million CAD ($5.4 million USD) from five investors to support our technological innovation, which will revolutionize sampling collection and testing for the oil and gas industry. This technology platform will make collecting the data required to reduce freshwater and chemical consumption uniquely accessible by providing an exponentially faster, on-demand approach. Interface Fluidics was founded in 2015 with the goal of revolutionizing how oil and gas

Finding Alternatives to PFAS with Microfluidics

Discussion of chemical use in the oil and gas industry is nothing new. But these days, justifying their application is becoming harder and harder to do. Recent studies have shown that even chemicals proven to be toxic are still in use today, despite bans in many parts of the world. Per- and polyfluoroalkyl substances (PFAS) are a group of chemicals known for their ability to help with oil extraction. Consisting