Blog

Stay Up To Date

Stay up to date on all the news and technology coming from Interface Fluidics.

Latest News

A New Proven Tool for Regain Conductivity

Select Chemistry approached Interface to help it overcome the well-known challenges associated with conventional regain conductivity testing: high variability, cost, and long turnaround times. The goal was to develop a solution that could not only overcome these challenges, but also provide additional insight into friction reducer damage and fluid optimization. “Given the inherent speed of microfluidic testing along with the small sample volume required for testing, our regain conductivity platform can be

Video: Polymer Enhanced Oil Recovery

Part of our mission at Interface is to help make oil recovery more efficient – particularly through enhanced oil recovery. Using our own reservoir-mimicking analogues, polymers and other EOR fluids can be injected under well-specific conditions to evaluate performance. This screening allows for better field decisions to be made by optimizing chemical type, concentration, slug size, injection rate, and more. Want to know more about our innovative polymer EOR technology?

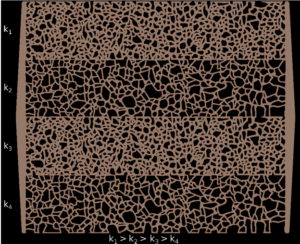

Applying Microfluidic Technology to Polymer Flooding Processes and Understanding Thief Zone Impact

As much as we would like to believe science to be a definitive process, it is often riddled with ambiguity. This is specifically apparent when it comes to applications of enhanced oil recovery (EOR), where conventional testing gives us only a snapshot of what a reservoir looks like. Operators of EOR processes find it particularly frustrating as most well sites are in regions of varying permeability, meaning that a chemical selected

Bringing Polymer Enhanced Oil Recovery Out of the Lab and Into Market

What is polymer enhanced oil recovery? Enhanced oil recovery (EOR), also known as tertiary recovery, is used to further produce oil after the primary and secondary phases of reservoir production. According to the US Department of Energy, enhanced oil recovery can extract 40-60% of the original oil in place, which is a substantial improvement over the 10% from primary recovery and 20-40% in place from secondary recovery1. EOR methods can

New Case Study for Regain Conductivity

From the beginning, Interface Fluidics has been working to bring innovative, efficient technology solutions to the oil and gas industry. Even passing conversations about a client need can lead to breakthrough research, as was the case with regain conductivity. Initially, our client was looking for a way to alleviate the concerns of traditional regain conductivity testing: the high costs, the slow turnaround times and the lack of test repeatability. The

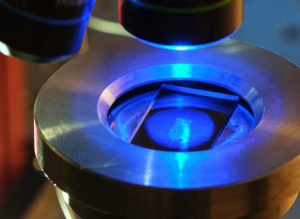

Maximizing Microfluidic Technology for Testing Minimum Miscibility Pressure (MMP)

Comfort exists in absolutes. For example, if you were renovating your kitchen, you might feel better if a contractor gave you an exact quote to redo your cabinets, rather than an estimate. Exact values like this provide us with a sense of security. And whether you’re debating granite vs. laminate or the parameters for a highly controlled process, it’s unlikely you’d prefer a ballpark estimate over a definite number.

Using microfluidic chip technology to test drive surfactants for SAGD bitumen recovery

You wouldn’t buy a car without test driving it, would you? No, the thought of this is ludicrous. Just because a certain make or model has been best in class for several years doesn’t decrease the merit of taking that spicy new sports car for a spin. In a world where “new” is often better, we fail to apply the same merit to scientific methods, instead relying on “tried and

Carbon capture and microfluidic technology: helping reduce CO2 emissions

Buried beneath the headlines of COVID-19 lies another global crisis. While tensions around restarting national economies increase, parallelly carbon emissions continue to predominate as an environmental stressor, accenting the need for countries to incorporate sustainability principles into their recovery plans. Despite the clean energy sector’s altruistic intentions, the infrastructure needed to transition to net-zero technology is still in its rudimentary stages. Thus, it has become apparent that the transition from

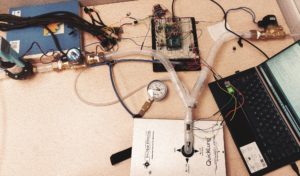

Interface Fluidics teams up with UofT on COVID-19 ventilator project

In the spring of 2020, a student team from the University of Toronto invited Interface Fluidics experts to work on their life-saving project: the development of a multi-patient ventilator to address high demand for patients with COVID-19 and severe respiratory diseases. Image credit: University of Toronto For a team that works predominantly with energy clients, fighting a global pandemic with health innovation might seem like a redirect. But with Interface’s

Interface’s environmental contribution to carbon capture and storage solutions (CCUS)

Interface’s measurements provide key information for advancing CCUS projects. Carbon Capture, Utilization and Storage (CCUS) is not a new idea in the oil and gas industry and has long been used to enhance oil recovery from a reservoir. Historically, the focus of CO2 injection has been on the economic benefits of more oil recovery. Today, utilization and storage of CO2 in a reservoir is quickly becoming a climate imperative and

Interface’s environmental impact reducing chemical use

Interface’s Fracturing Flowback solution optimizes chemical usage. Over the past couple of years, the oil and gas industry has been focused on minimizing its carbon footprint — with many aiming to become a net-zero carbon company in 10 to 20 years. At Interface, we believe mitigating environmental impact is just good business. We’re helping our clients do more with less, responsibly. Reduced chemical usage Using less has immediate benefits. Working with Primexx Energy

Interface Minimum Miscibility Pressure Measurements

Equinor and Interface partner to develop fastest and most accurate measurement for minimum miscibility pressure “Interface’s minimum miscibility pressure measurement is a disruptive technology that has changed how we work at Equinor. MMP measurements are now cost effective and timely which has changed them from a nice to have to a need to have for our team.” Tao Yang, Reservoir Technology Specialist of Equinor Note: If the video does not