Smaller Is Better? HSE Benefits of Working with Interface

The Health, Safety, and Environmental (HSE) aspects of reservoir fluid analysis are a priority for Interface Fluidics. While traditional lab analysis requires multi-liter samples, Interface’s microfluidic technology cuts that down to a few milliliters – which diminishes HSE impacts like the potential release of hazardous substances.

Advantages of smaller sample sizes include easier and more energy-efficient collection, as well as convenient and cost-effective shipping. For Interface, the reduced sample size also results in more effective handling and storing in our lab – where it is analyzed under high pressures and temperatures – which requires robust HSE procedures.

This means our proprietary microfluidic technology significantly reduces associated risks – showing Interface’s commitment to upholding the highest standards of health and safety in our lab.

In this article, we’ll compare the HSE risks of traditional testing with Interface’s technology, comparing the lab equipment used and the contained energy of the samples involved.

The Testing Equipment – An HSE Comparison

Lots of conventional laboratory equipment operates at High-Pressure High-Temperature (HPHT) and contains large volumes and contained energy. At Interface, the equipment we use is small and very controlled, so even in the case of a catastrophic failure, risks are minimal.

Contrary to the substantial volumes used in traditional testing, Interface nano to micro-litre device loading volumes mean that we can safely operate at extremely high pressures and temperatures – reaching as high as 1000 bar at 200 ℃.

Though more detailed comparison can also be found in a previous blog post, Interface’s proprietary technology offers the following advantages:

- Our device holds 0.82 uL. At the same pressure as a compressed gas cylinder, that’s the contained energy equivalent of lifting an apple 35 cm off a table – not nearly enough energy to cause significant harm.

- The supporting equipment including lines, fittings, in-line filters, etc. doesn’t exceed 5 mL, far smaller than any core flood rig or PVT cell used in conventional labs.

- How do we see a system failure? We observe a slight increase in flow rates and may capture analogue leakage under the microscope.

- Despite the low contained energy, our system is still equipped with rupture discs, pump hardware clutches, and software pressure control settings.

In contrast, in conventional fluid analysis, large HPHT devices are often utilized. An autoclave is an example of such a device. While primarily used in healthcare, manufacturing, and research, it provides a valuable example of the risks associated with HPHT technology.

In December 2019, a severe explosion occurred in Kansas – the culprit? – the elevated temperature and pressure of an autoclave. The blast led to 15 workers being critically injured and a dozen nearby parked cars left mangled.

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) penalized the company involved due to the “catastrophic thermal fatigue failure” – which exposed workers to “amputation, broken bones, concussions, crushing, laceration and struck-by hazards”.

Compressed Gas and Its Contained Energy

Now let’s compare the compressed gas cylinders used by Interface to those used by the compressed gas industry examples from around the world.

Dangerous compressed gases include oxygen, nitrogen, hydrogen, and many more. Factors like physical Impact, heat, corrosion, or dents in the container amplify the chance of an explosion. Therefore, For HSE compliance, strict storage conditions must be met, such as storage in a fire-resistant, cool, dry, and well-ventilated area.

A recent trend in Southeast Asia saw an underregulated switch to cheap liquified petroleum gas. Without adequate compressed gas safety measures, thousands have lost their lives, and more than twice as many have been gravely injured due to explosions.

This problem is not unique to developing countries.

The compressed gas industry in the United States dates back to the early 1900s when production of acetylene and oxygen began on a large scale. However, compressed gases can be flammable, oxidizing or reactive which increases the risk of an explosion.

According to The United States Bureau of Labor Statistics, compressed gas accidents in the U.S. are widespread, amounting to 20 deaths and 6000 injuries per year. Compressed gas accidents include explosions, fires, chemical burns, asphyxiation, and high-pressure accidents.

Energy Contained in Compressed Gas

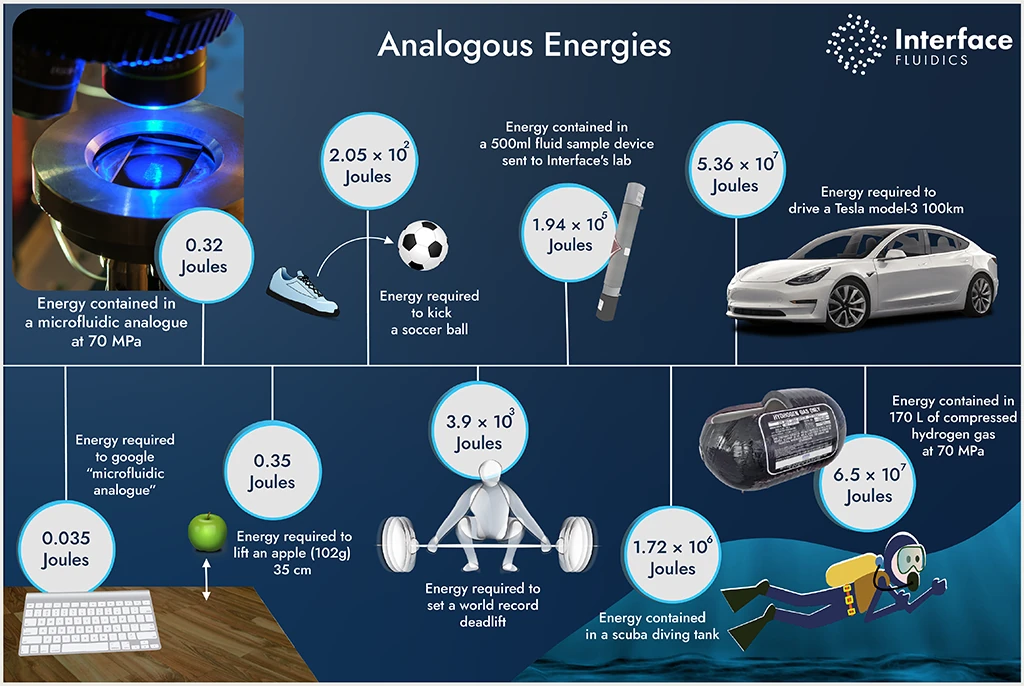

In the following graphic, a sharp contrast is seen between the energy contained in Interface’s microfluidic analogue and the energy contained in a compressed gas cylinder – which is several orders of magnitude higher. Even the energy contained in a 500 mL cylinder sent to Interface’s lab is 335 times less than that contained in 170 L hydrogen tank pressurized at 70 MPa.

Interface’s Culture of Safety

The number of compressed gas accidents around the world each year is not negligible and should not be ignored. As Interface miniaturizes HPHT testing, the 99% smaller sample volume is much more environmentally benign both in the lab and during shipping – reaping the benefits nanotechnology has to offer.

The health and safety of individuals, our staff and energy professionals is a priority for us that forms an integral part of the Interface brand – that’s why we continue to adhere to the highest standards of HSE and remain vigilant in monitoring our microfluidic analogues to ensure the well-being of all involved.

Over the course of six years of continuous innovation, Interface’s pressure capability and the types of tests we can perform proliferated to include a wide solutions portfolio – where an array of safety tests are executed on each product before bringing it to the market.

Find out more about our microfluidics tests on our Solutions page or YouTube channel, and follow us on LinkedIn to stay up to date with our latest events and developments. Feel free to contact us at Info@InterfaceFluidics.com with any questions – we’d love to help you explore how microfluidics can make your reservoir operations more efficient.