Interface’s Fracturing Flowback solution optimizes chemical usage.

Over the past couple of years, the oil and gas industry has been focused on minimizing its carbon footprint — with many aiming to become a net-zero carbon company in 10 to 20 years. At Interface, we believe mitigating environmental impact is just good business. We’re helping our clients do more with less, responsibly.

Reduced chemical usage

Using less has immediate benefits. Working with Primexx Energy Partners, we helped them significantly reduce the volume of surfactant used in their fracturing operations.

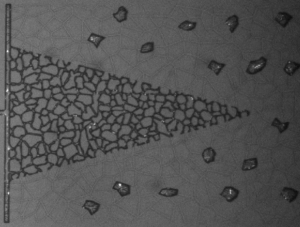

Prior to engaging Interface, Primexx was injecting an established surfactant at a typical rate of 1.5 L/m3 of injected water. Interface measured the effectiveness of this chemical treatment, and evaluated other surfactant candidates, at a range of concentrations. We found that an alternative surfactant could offer superior performance with the client’s particular reservoir fluids and conditions at much lower concentrations. After Interface’s testing and analysis, Primexx switched to the alternate surfactant, using a third of the concentration previously used (0.5 L/m3).

Not only did lowering the surfactant volumes have a strong economic return, it also had an environmental benefit by mitigating CO2 emissions. At the simple end of the spectrum, less surfactant transported and injected means less energy consumed in the process.

At the other end of the spectrum, commercial production of surfactants results in major CO2 emissions. Surfactants are produced at a rate of 14 Mt/yr globally and the production of each tonne of surfactant results in ~4.7 tonnes of CO2, on average [1]. The volume of surfactant saved by Primexx in each well corresponds to 35 tonnes of CO2 emissions avoided — the equivalent of taking seven cars off the road. Applied to a larger field program, this amounts to a large reduction in aggregate CO2 emissions. The Primexx achievement illustrates how doing more with less is good business and has a positive climate change impact.

[1] Patel, M., Theiß, A., & Worrell, E. (1999). Surfactant production and use in Germany: Resource requirements and CO2 emissions. Resources, Conservation and Recycling, 25(1), 61-78. doi:10.1016/s0921-3449(98)00063-9