PVT and Fluid Phase Behaviour

Faster and more cost effective high-pressure, high-temperature analysis of oil and gas samples.

Interface’s suite of standard and advanced PVT analysis solutions require less than 1ml of fluid per evaluation and gets you results much faster than conventional PVT methods.

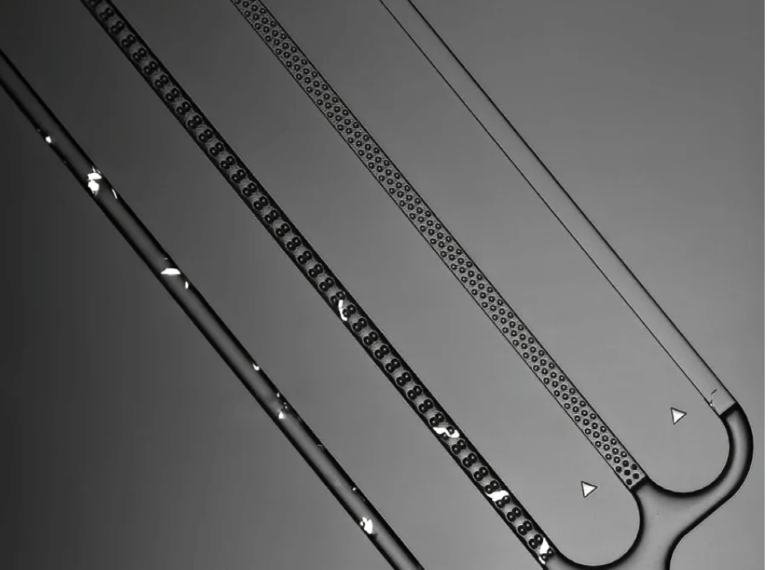

Minimum Miscibility Pressure (MMP) and Composition

Rapid Measurements For Gas Flooding

Quickly determine miscibility conditions for your gas flooding operation with a variety of gas compositions. MMP measurements provide you the minimum pressure required for miscible oil displacement in your reservoir. This critical measurement helps you avoid unwanted early gas breakthrough, which reduces oil recovery.

Developed in partnership with Equinor, this test is proven to deliver accurate results in as little as 30 minutes with as little as 0.1ml of oil sample per data point.

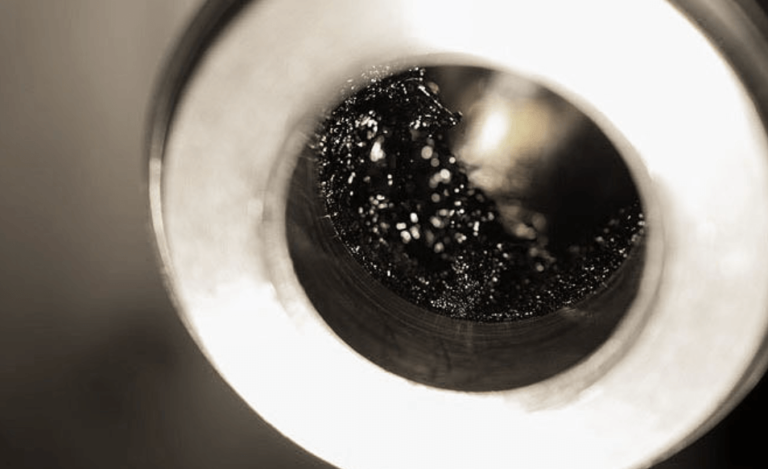

Asphaltene Onset Pressure

Flow Assurance For Light to Medium Crudes

Prevent asphaltene damage in your reservoir with critical information on asphaltene dropout conditions. Using less than a ml oil sample along with our unique high-pressure, high-temperature microfluidic technology platform, Interface can detect the onset condition of asphaltenes under varying reservoir conditions.

Bubble and Dew Point

Analysis For Research and Surface Facilities

Rapidly measure bubble point as part of a larger PVT study. Determine dew point for retrograde condensate reservoirs or for surface facilities such as CO2 pipelines.

The majority of hydrocarbon fluid properties abruptly change once the reservoir pressure reaches either bubble point or dew point. Interface gives you accurate measurements of bubble and dew points for your reservoir fluids.

Wax Appearance Temperature

Flow Assurance Study

Guarantee better fluid transport and flow assurance by understanding wax onset conditions. Our microfluidic wax appearance temperature (WAT) analysis combined with high-resolution, cross-polar microscopy gives you reliable and repeatable WAT data with an accuracy of ±0.5 °C under a wide range of pressure.