Since December 2023, the Interface Fluidics Team has been hard at work building two of the most advanced high-pressure microfluidics systems in the world. PTT Exploration and Production Company (PTTEP), with a lab based just north of Bangkok, and The Pontifical Catholic University of Rio de Janeiro (PUC Rio) ordered these SapphireLab systems to enhance their laboratory capabilities for both fluid property measurements and characterization of flow through porous media.

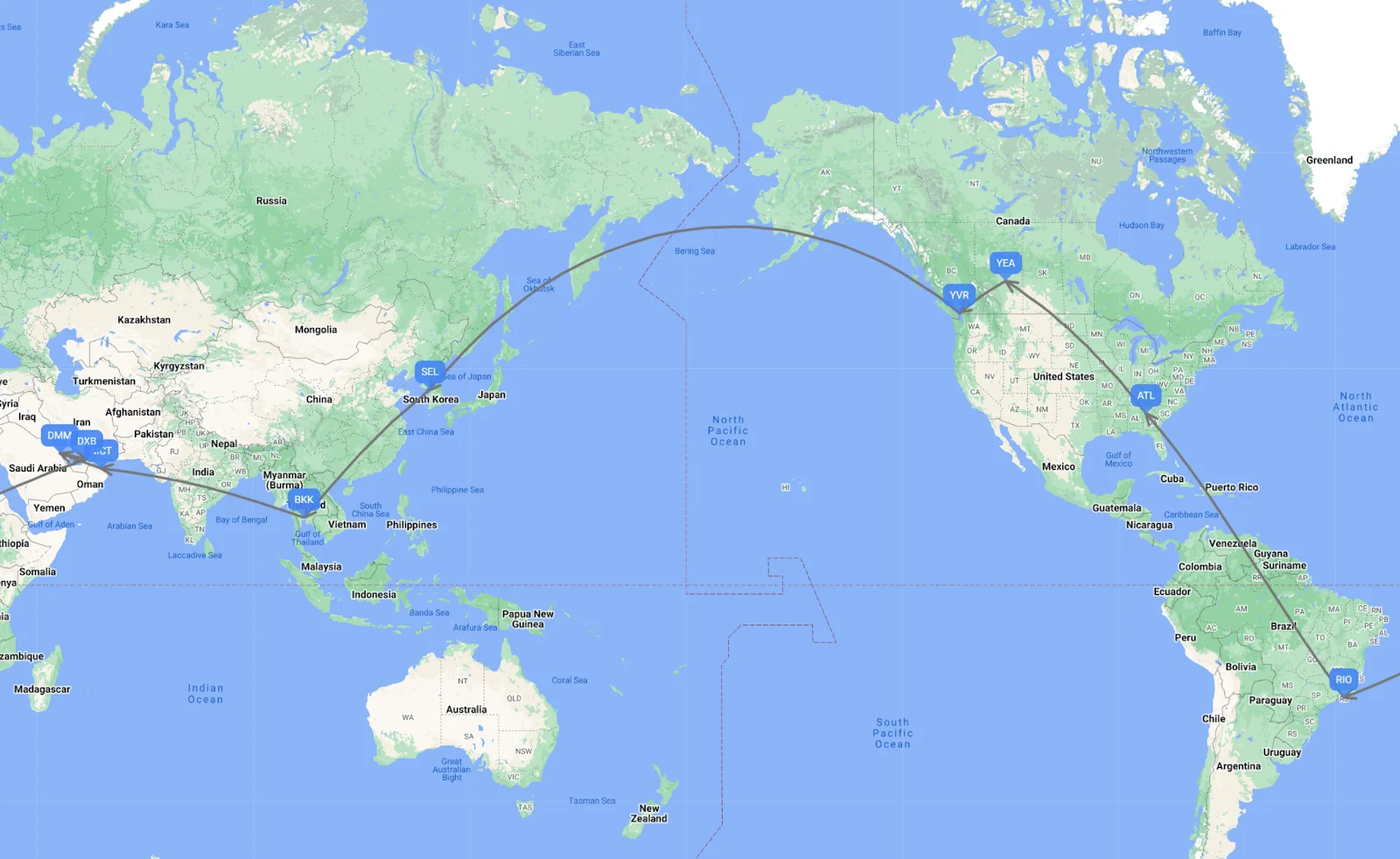

The installation of these two systems together with a visit to our customers in the Middle East would take me around the world over a period of 30 days. For the installation in Thailand, I would be accompanied by one of our most experienced laboratory technicians, Xinyue (Amy) Zhang. Amy has over five years of experience running complex microfluidic porous media and MMP testing projects at Interface. Amy and I arrived in Thailand after two layovers on June 29th. To complete the installation in Thailand, we worked with ILAB Fluid Control. ILAB would be handling the local maintenance support.

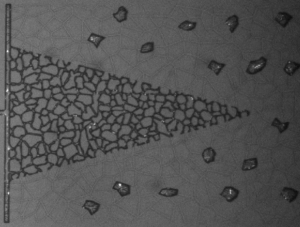

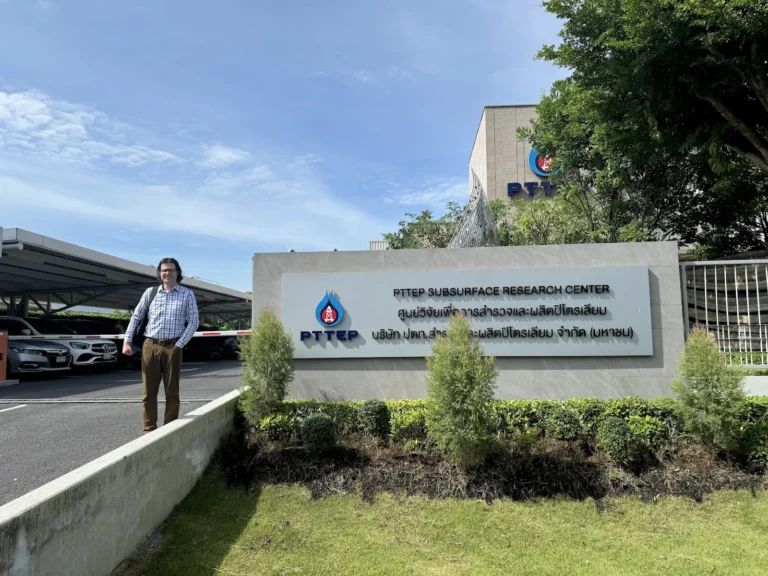

We arrived at the PTTEP Subsurface Research Center on Monday July 1st. PTTEP had purchased a SapphireLab EOR system to help them optimize their gas injection projects. I would be at the lab for a week and Amy for two weeks in order to commission the system and provide training. I was really impressed with the knowledge of microfluidics that the researchers at PTTEP had. This made the training much easier. We were also lucky to work with the technicians at ILAB and PTTEP who all had a lot of high-pressure equipment background. Suvimol from ILAB was a great host and in addition to coordinating shipping and maintenance activities, she brought us out to eat at some great local Thai restaurants. Over the two weeks that Amy was at PTTEP, she trained the team on how to run four different tests.

While Amy was finishing training, I left Thailand and headed out to start my tour of the Middle East in Muscat, Oman. Muscat is a beautiful city with a rich history and is also home to one of our customers, Petroleum Development Oman, and one of our investors, Phaze Ventures. I was only in Muscat for a short time but I did meet with several groups at PDO as well as with Ahmed Al-Salmi from Phaze Ventures. I also tried some of the local food like this fancy Shuwa Risotto.

After a short stop in Dammam, I continued my trip to Dubai where I would spend two nights before heading to Rio de Janeiro. In Dubai, I connected with Abdullah Al-Shaksy from Phaze Ventures and had a few other productive meetings with potential customers. It was so hot in the Middle East, that I decided it was time to cut my long hair down to something cooler. With a new hairdo, I was on one of the longest flights that I had ever taken (15 hours) from Dubai to Rio.

I landed in Rio de Janeiro on Friday July 12th, 2024. I had the weekend to see the city before starting the commissioning of the SapphireLab system at PUC Rio. Taylor Latorre, one of Interface Fluidics’ Senior Lab Technicians, would be meeting me in Rio to commission the SapphireLab Pro system and provide training to Prof. Marcio Carvalho’s team at The Laboratory of Microhydrodynamics and Flow in Porous Media (LMMP). Rio is one of the most beautiful cities that I have ever visited. It was a treat to get to see the city over the weekend.

I was really impressed by the facilities that the LMMP lab has at PUC-Rio. They have extensive core flooding, rheology, and microfluidics capabilities. Also, the first lab I have seen with granite lab benches everywhere. Jorge, Brenda, and Yan were the main folks that Taylor and I trained on the equipment. They all had lots of experience in both high-pressure systems and microfluidics which made the training much easier. The LMMP lab would be using the SapphireLab system to conduct PVT tests as well as porous media tests so there was a lot of training to do. Taylor showed the team how to run five different measurements over the course of the two weeks that we were there.

Throughout the time that we were at the LMMP Lab, we also visited five energy companies that operate out of Rio. We discussed the capabilities of the SapphireLab platform as well as the speed, safety, and sample volume advantages of using a microfluidic system compared to legacy systems. After many long days in the lab, the system was commissioned and the team was trained on how to run all the needed tests. It was time to head back to Canada.