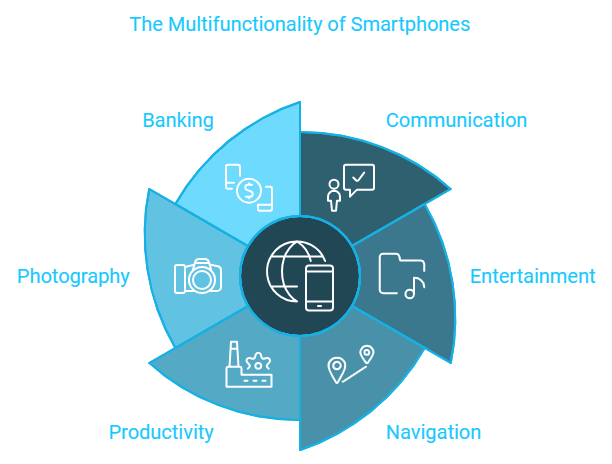

In the early days of the smartphone, most of us were thrilled to have a portable device that enabled us to make calls, text friends or colleagues, check our calendars, email others and surf the internet. We didn’t realize at the time, but it would also become our go-to-camera, calculator, flashlight, alarm clock, TV, newspaper, radio, file cabinet, photo album, banking machine, credit card and map, to name a few of the many devices it has replaced (or at least complemented). As well, most of us didn’t even consider the new capabilities it would spawn, like finding the best route for your drive home, finding you a date, booking a table at your favorite restaurant or calling for a ride.

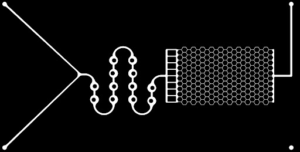

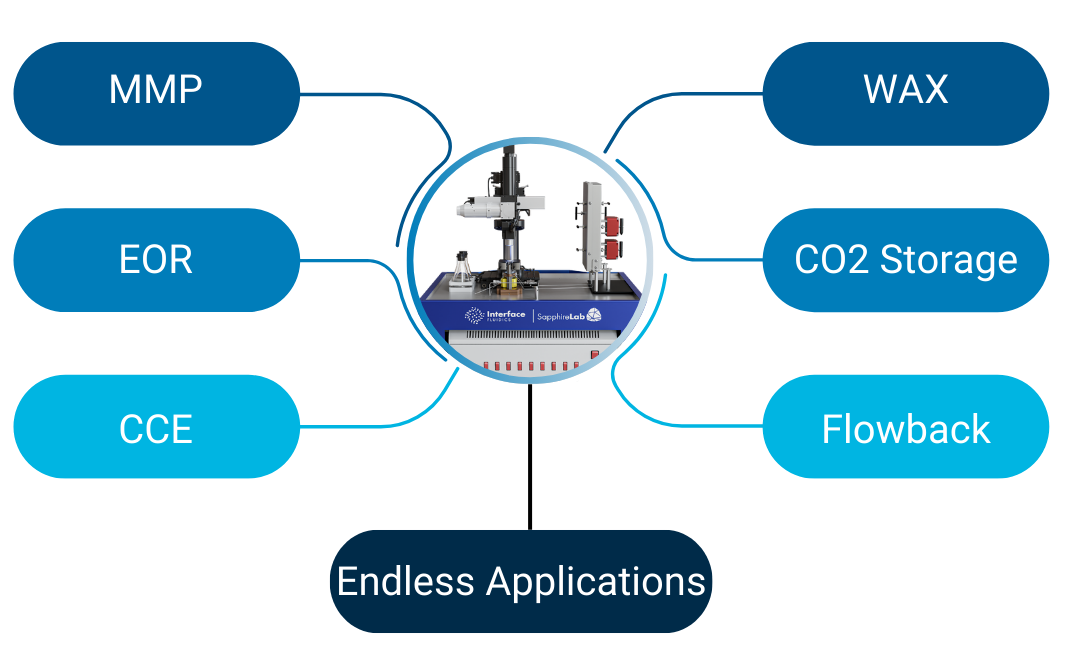

While it may be hyperbole to suggest it, let alone market it as such, our vision for SapphireLab is to bring that same smartphone-like versatility to industrial fluid analysis. In other words, simplifying complex measurements into one portable device. Following this analogy, if SapphireLab is the smartphone, our microfluidic chips (along with our standard operating procedures and image analysis software) are the apps. Are you interested in measuring a different fluid property or visualizing different fluids interacting at the micro or nano scale? No need to use a different piece of equipment. With SapphireLab, you can simply insert a different microfluidic chip and follow a different procedure, as easily as you switch between apps on your smartphone.

Today’s industrial laboratories in the energy sector use numerous devices such as PVT Cells, Slim Tubes, Core Floods, or Proppant Packs to make standard fluid property measurements or to study fluid interactions. Each device has its own upfront cost, requires regular maintenance, takes up valuable laboratory space and requires training and know-how to successfully make a measurement. Our vision of the future industrial laboratory is that instead of having all of these devices and associated costs and training requirements, most of the key fluid measurements could be completed using a single multipurpose microfluidic system like SapphireLab. In fact, taking it a step further, we believe it would be preferable to bring the instrument out of the laboratory and into the field to make measurements and decisions in near real-time. Just like we carry around a supercomputer wherever we go, we aim to make fluid measurements conveniently portable.

In the near term, SapphireLab and other microfluidic systems will begin to replace or complement existing traditional fluid testing instruments, much like the smartphone started by bringing together capabilities of other known devices like the calculator or alarm clock. However, just like the smartphone brought us automated route finding, microfluidics will introduce us to a bevy of new capabilities never thought of before. In fact, if you look closely enough, it is already happening, with SapphireLab’s Flowback measurement as an example.

In today’s world, we have grown accustomed to the convenience and utility of smartphones, where the potential uses are only limited by the imaginations, time, money and know-how of creators who design the apps. We see SapphireLab in the same light. While today, SapphireLab may offer only a dozen or so different fluid apps, with every new microfluidic chip we develop, SapphireLab’s capabilities expand, bringing us closer to a future where fluid analysis is as intuitive, portable, and powerful as the smartphones in our pockets.

Ready to explore the future of fluid analysis? Discover more about SapphireLab and how it can transform your lab by visiting our SapphireLab website.

1 Lauren. (2024b, September 21). Mobile App download Statistics & Usage Statistics (2024) — BuildFire. Buildfire. https://buildfire.com/app-statistics/.