Why Fluids Matter

You’ve invested the time, effort, and capital, investigating where next to drill. After locating oil, it’s time to set up your drilling production. Right? Wrong.

Oils found across Alberta have massive variability and are much different than oil found in the Permian Basin in the United States, and even more different than oil drilled in the North Sea. These differences in molecular composition, and the reservoir they were discovered in, have a massive impact on how a drilling and completions operation should be stood up and executed. To further complicate things, each reservoir, and more specifically each well, can respond differently when being completed and produced.

There is a fundamental tension in the oil and gas production industry regarding the issue of attention. We know that closely managed wells produce more because we can treat them as individuals. However, we also know that giving individual attention to the tens of thousands of new wells drilled around the world each year is impossible. This leaves engineers looking for high-impact, short time framed options to improve production – options that mimic the individual attention wells need. Tools like machine learning, automated control systems, and data science, all have a role to play – but these tools don’t address the fluid issue. The question remains – how is the expensive chemistry I’m using in my completion or production plan affecting the economics of my well? Am I injecting enough, or too much, of the right product?

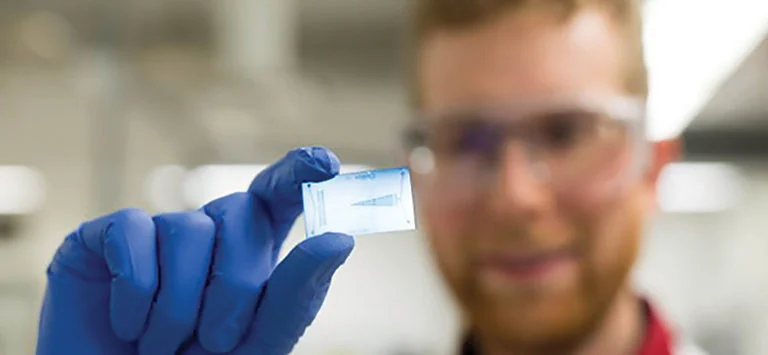

One way is fluid analysis.

Chemical additives can often assist an operator in recovering more product from a well. In new wells, chemicals added to fracturing fluids affect the ultimate oil recovery. In declining wells, chemistry is injected into reservoirs to increase production by mobilizing oil that is trapped or otherwise unable to be produced without some form of assistance. But with hundreds of different additives available, it can be tough to know without testing which ones will actually help you recover more, and which ones could be damaging your very expensive well. As a well ages, its needs can change dynamically over that time, and production strategies need to change with them. This makes fluid testing and characterization continuously important.

Just like an insulin prescription is given based on individual circumstances, engineers and geoscientists study the fluids in a reservoir to find the right prescription for that well. An enhanced understanding of geology, oil, and completion/production fluid properties gives engineers the best odds of recovering the most amount of oil. It requires fast, repeatable testing, much like what blood. Recovering more hydrocarbons from a single well is better not only for a producer’s bottom line, but it also benefits the environment by enabling alternatives to fresh water.

There is a wide variety of fluid analysis available, but the testing options that you choose should be relevant to your unique reservoir. At Interface, we have numerous fluid testing options that can be applied to conventional and unconventional resources, as well as in SAGD operations. Connect with us today to see how our testing and analysis can help your bottom line.