Interface Minimum Miscibility Pressure Measurements

Equinor and Interface partner to develop fastest and most accurate measurement for minimum miscibility pressure

“Interface’s minimum miscibility pressure measurement is a disruptive technology that has changed how we work at Equinor. MMP measurements are now cost effective and timely which has changed them from a nice to have to a need to have for our team.”

Tao Yang, Reservoir Technology Specialist of Equinor

Microfluidics in Oil & Gas: Minimum Miscibility Pressure

Interface Fluidics has developed the first system that can measure MMP in just a week, at reservoir conditions, using just a few mL of live fluid sample. At this webinar, Interface will present the technology that has enabled this breakthrough, the details of our method, and talk about how we are disrupting the industry with this technology.

Challenge

- Develop an alternative method for measuring miscibility conditions including Minimum Miscibility Pressure (MMP) and Minimum Miscibility Enrichment (MME)

- Reduce the time, cost, and sample requirements compared to slim tube method

- Validate the method for the distinct miscibility drive mechanisms, Condensing, Vaporizing, and combined Condensing/Vaporizing drive.

Solution

- Miniaturize the traditional slim tube style apparatus using microfluidic technology

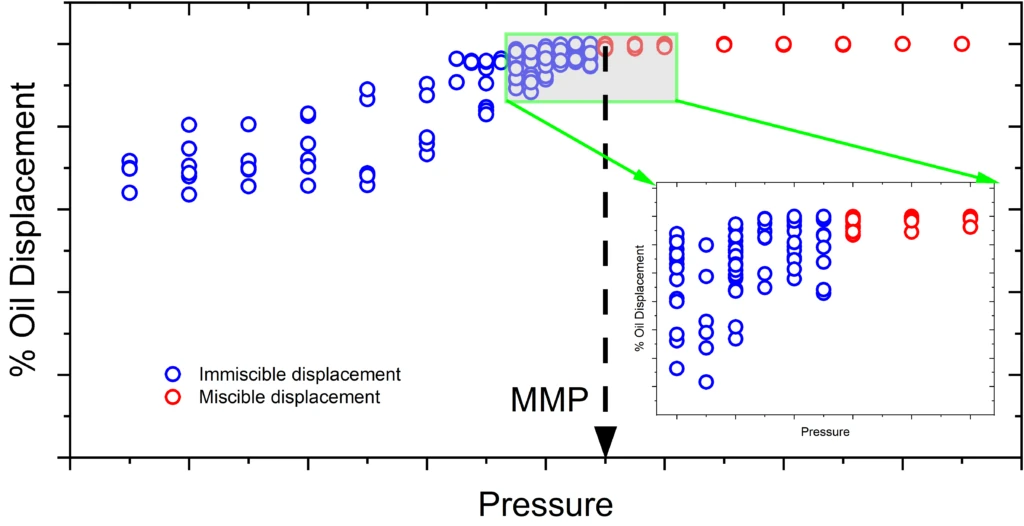

- Develop a machine-vision based measurement for determining miscibility condition

Results

- Time per measurement reduced by over 95% (1 week per MMP)

- Achieved ± 2.5 bar (±35 psi) measurement accuracy

- Sample volume requirement reduced by 99% (10 mL live oil sample)

- Validated miscibility drive mechanisms for most field applications.

The Goal

Equinor is an international producer of oil, gas, and renewable energy headquartered in Stavanger Norway with operations in major onshore and offshore basins worldwide. The team at Equinor approached Interface with a challenge – develop a replacement for slim tube testing for the determination of Minimum Miscibility Pressure. The measurement is critical in all of Equinor’s fields where gas injection is used or will be implemented, but the cost, time, and logistics associated with the traditional measurement technique was prohibitive.

Results

Interface developed, in close collaboration with Equinor on design, a slim-tube style microfluidic device. It was validated by measuring the minimum miscibility pressure of three live oil samples and selected gas mixtures from different fields with different mechanisms. Interface’s technology reduced time per measurement by over 95%, reduced of sample volume by 99%, and eliminating the need for mathematical interpolation of results by increasing the number of measurements taken per sample by 10-20X. The samples chosen exhibited most observed drive mechanisms in field operation. Results were compared to slim-tube experimental data and deviations were 2.8% on average.